- Green

procurement - Control of environmentally

-unfriendly chemicals - Compliance with RoHS

Directive and REACH

In order to deliver environmentally friendly products to customers, it is vital to ascertain the chemical content of not only our own products but also those of suppliers and to disclose and communicate such information smoothly. For this purposes, we are striving to establish a system covering the entire supply chain.

Cosel established its Green Procurement Standards in FY 2004 and has used them as conditions of transactions with suppliers since then. We also conduct regular review for compliance with laws and regulations and promote green-procurement efforts.

Management of new components, new products, and mass-produced products

Since FY 2006, Cosel has employed a system that uses X-ray fluorescence analysis(*) of individual components to exclude contamination by chemicals harmful to the environment. Through this X-ray fluorescence analysis, we confirm and verify compliance with the RoHS Directive.

Adoption of new components and introduction of new products

When employing a new component, we ask the suppliers to submit a Warranty for Non-inclusion of RoHS Materials to verify that it does not contain any substances restricted by the RoHS Directive. Furthermore, we obtain a list of materials used in each component and check the actual component against the list to make sure that there are no omissions. Then, we compare data on chemicals harmful to the environment with the results of X-ray fluorescence analysis and register only those components that have been found to present no issues.

Acceptance of purchased components

We also conduct X-ray fluorescence analysis at the stage of acceptance of components, employing a frequency based on the applicable risk rank, to check whether components delivered contain any chemicals harmful to the environment.

X-ray fluorescence spectrometer

X-ray fluorescence analysis(*)

X-ray fluorescence analysis is a method of analysis in which the atoms in a molecule are irradiated with X-rays to identify the atoms present in a sample from the characteristic wavelength and energy intensity of the X-rays reflected from them.

Operation of a portal site for suppliers

Since June 2017, we have used a portal site developed in house to enable efficient data collection through exchange of data from suppliers on content of chemicals harmful to the environment and our own green procurement standards.

Education on management of chemicals harmful to the environment

We have carried out education on management of chemicals harmful to the environment since FY 2006.

This program is intended for people working for Cosel at our Head Office Factory and Tateyama Factory and at our OEM manufacturers, logistics contractors, and repair contractors.

Using training material developed by the division in charge of environmental management, this training is conducted as part of internal training by departments. Trainees are tested to check their level of understanding. This helps to deepen their understandings of the objectives and importance of managing chemicals harmful to the environment as well as the details of Cosel's initiatives.

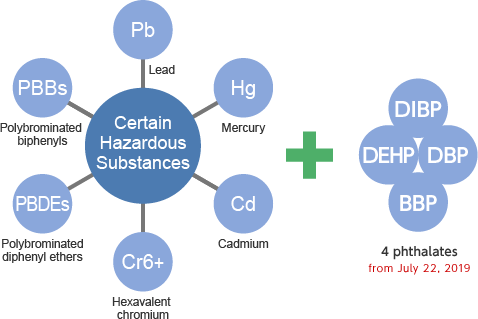

The RoHS Directive came into effect on July 1, 2006(*1). It restricts the use of six substances that negatively impact the human body and the natural environment (mercury, lead, cadmium, hexavalent chromium, PBB, and PBDE).

Furthermore, the Directive was revised on January 3, 2013. Although the restricted substances and their tolerated maximum concentration values remain the same in the revised Directive (2011/65/EU: RoHS2), the number of subject product categories was increased and CE marking requirements were added.

Cosel achieved full conformity to the limits on the content in our products of these six substances specified by the RoHS Directive in February 2006 and began displaying the CE mark in accordance with the RoHS Directive in June 2015(*2).

The EU Commission Delegated Directive (EU) 2015/863 added four phthalates(*3) to the substances subject to the RoHS Directive in June 2015, and the number of restricted substances was increased from six to 10 on July 22, 2019.

We are responding through means that include investigating the content of the four phthalates contained in our products and checking on production processes.

In May 2020, we fully discontinued our eutectic solder products.

The REACH regulations also require all companies manufacturing or importing chemical substances in quantities of one ton or more per year in the European Union to register information on those substances in the European Chemicals Agency (ECHA) database.

Failure to register means the substance may no longer be manufactured or imported in the EU.

Since new substances are added to the REACH list of Substances of Very High Concern (SVHC) every half year, we expect suppliers to provide the latest information on contained substances in a timely manner.

Information on compliance with the RoHS Directive and information on SVHC content under REACH Regulations are published in certificates of non-use of RoHS substances and provided on our website as data for use with the chemSHERPA tool for communication of information on environmentally harmful chemical substances, developed by the Ministry of Economy, Trade and Industry and operated by the Joint Article Management Promotion-consortium (JAMP).

- *1 RoHS Directive

An EU directive that restricts the use of certain hazardous materials in electrical and electronic equipment.

The use of six substances (mercury, cadmium, lead, hexavalent chromium, polybrominated biphenyls [PBBs], and polybrominated diphenyl ethers [PBDEs]) has been prohibited since July 2006. - *2 Not including some products for which cessation of production is planned

RoHS-compliant products are identified by the letter "R" at the end of their lot numbers. (Some models show have the letter "R" in the upper right of the label.) - *3 4 phthalates

Bis(2-ethylhexyl) phthalate (DEHP)

Butyl benzyl phthalate (BBP)

Dibutyl phthalate (DBP)

Diisobutyl phthalate (DIBP)