Promoting the "Three R's" (reduction, reuse, recycling)

Cosel promotes the "Three R's" based on the perspectives of lessening environmental impact and effectible use of resources.

We will continue thorough efforts to reduce, recycle, and segregate wastes in our business activities in the future as well.

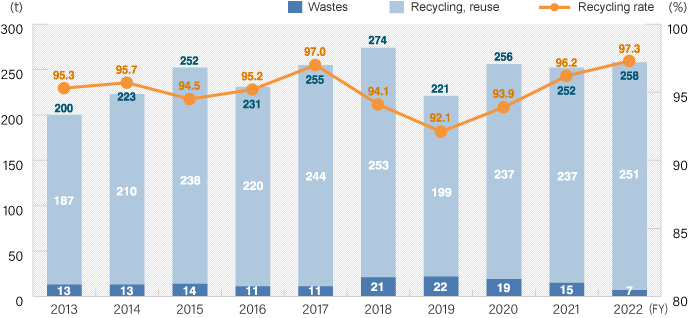

Trends in wastes and recycling rates

Examples of initiatives

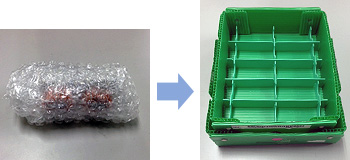

Reduction

Previously, we had used bubble wrap bags to send certain components to our OEM manufacturers. After unpacking, these were disposed of as industrial waste. We were able to reduce the amount of waste by adopting a new packing method using reusable returnable containers. We also improved the reusability of these containers through means including use of rubber bands to keep their lids in place.

Bubble wrap bag

Reuse

Chip components are delivered wound on plastic reels like tape. Previously, we had disposed of the used reels as stable industrial waste.

But since the reels were neither deformed nor soiled after use, we asked the suppliers to collect and reuse them.

Recycling

Defective units that could not be shipped as products and substrate scraps cut off in the production process had been disposed of as industrial waste. Now, we separate them into metals, plastics, and other materials before disposal, so that they can be used to cast ingots or as auxiliary combustion materials in furnaces. We regularly check the status of waste segregation and strive to raise employees' awareness.