Lessening environmental impact at production sites

In-house development of automatic soldering equipment

To lower assembly costs by half, we are deploying in our production lines soldering devices that we developed in-house. Compared with conventional soldering equipment, these devices help to lessen environmental impact by greatly increasing equipment capacity.

Soldering equipment developed in-house

Comparison to conventional tank (type B)

![Reduced ratio[Equipment cost reduction:32%][Auxiliary material cost reduction:48%][Maintenance man-hour reduction:60%][Area reduction:25%]](/corporate/csr/environment/monodukuri/images/img01.png)

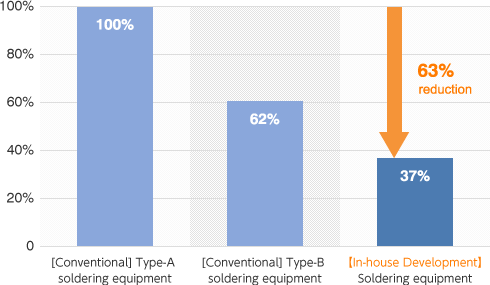

Power consumption efficiency compared to conventional tank

(Comparison to conventional type-A soldering equipment)

Units of soldering equipment (facilities) adopted/CO2 reductions