1. What is heat cycle test?

Heat cycle test is a test to confirm the effect on power supply caused by the repetition of temperature change.

There are the reasons why Heat Cycle Test Is necessary.

- (1)The sample is basically abstracted by different material which has different thermal vapor ratio.

In this case, reactive power is appeared on the surface of two different materials.

It would cause the crack of soldering point and cause failure of power supply. - (2)Same as (1), soldering point would be cracked due to the difference of thermal expansion ratio between internal components and printed wiring board.

In case of power supply, the influence of (2) is higher. Therefore we focus on the soldering point condition at the thermal cycle test,

And the maximum withstanding-ability to heat cycle test is depending on the following items.

- (1)Test Temperature (Low/High).

- (2)The exposure time at low/high temperature condition.

- (3)The temperature changing speed between Low and High.

- (4)The number of testing cycles

- (5)The amount of thermal conduction to the inside/outside of the power supply

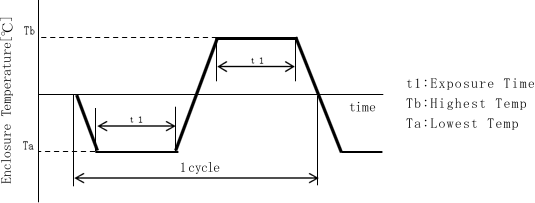

2. Test conditions of Temperature Cycle Test

The general conditions of heat cycle test are shown below.

- (1)Highest Temp. [Tb] : 125℃

- (2)Lowest Temp. [Ta] : -40℃

- (3)Exposure time [t1] : 30 minutes each

Fig.2.1 Temperature change in the temperature cycle examination

3. Lifetime estimation of soldering point

The lifetime of soldering point under the actual operating conditions can be presumed based on Coffin-Manson method.

Technical Product-related Inquires

e-mail:support@cosel.co.jp